Service

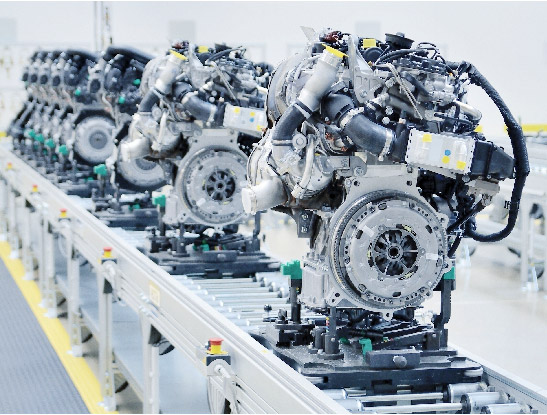

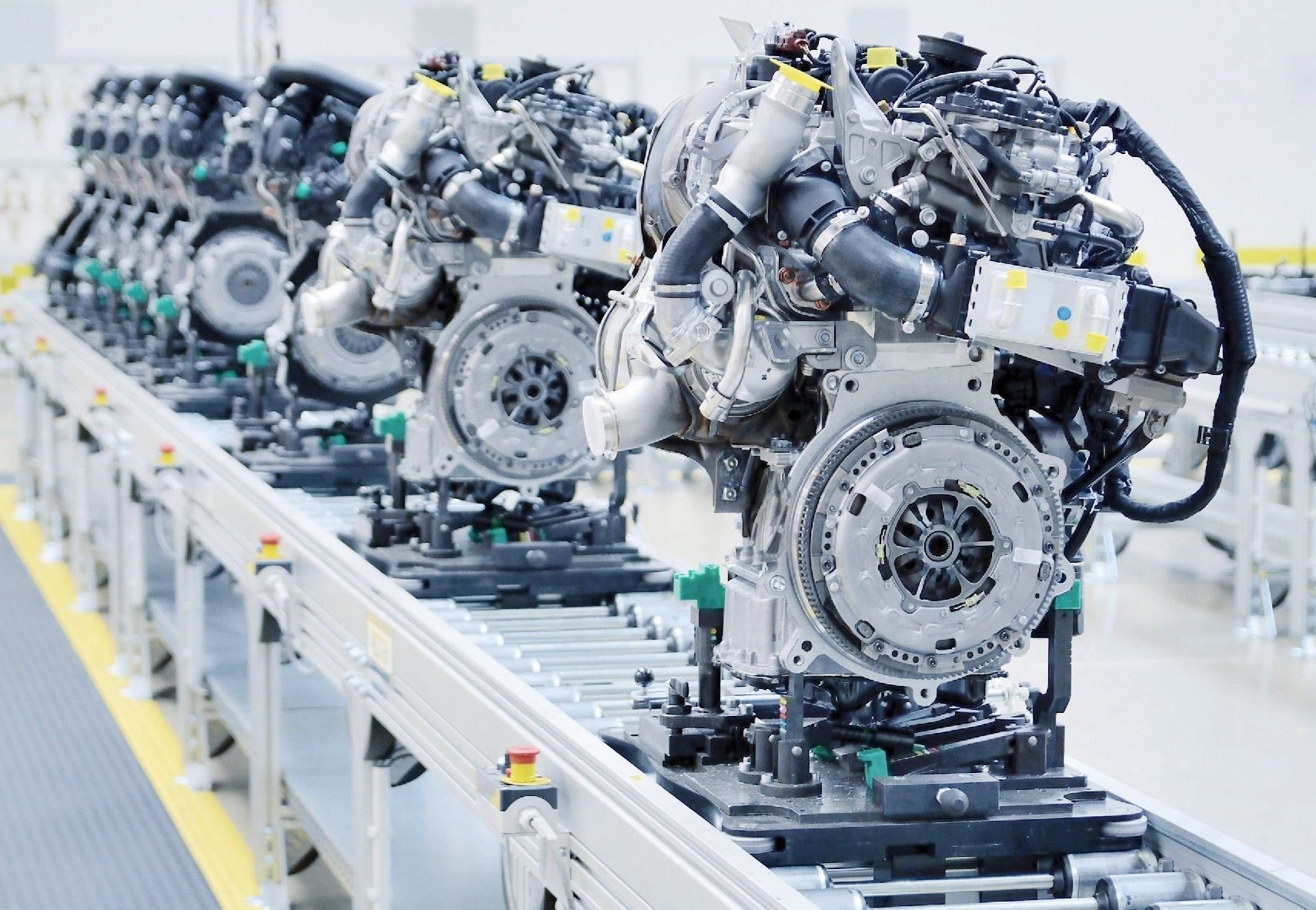

Industrial Machinery & Tools

Construction & Engineering

Study "Genba" and propose improvements from "Genba"

"Small Kaizen" for Customers

Why choose us.

We are an engineering company that can also develop and design systems on our own.

TOMAS ENGINEERING is an engineering company that mainly provides services to customers in manufacturing industry. Our services cover three fields: IT (IoT / AI), industrial machinery & tools (safety / CR / environment), and construction & engineering. We provide customers the approach of "Small Kaizen" especially in the IT (IoT / AI) field. As we can also design and develop systems that suits specific customer requirements on our own, production improvements can be sold in packages, started minimally, at low cost, and with quick delivery.

Service

Industrial Machinery & Tools

-

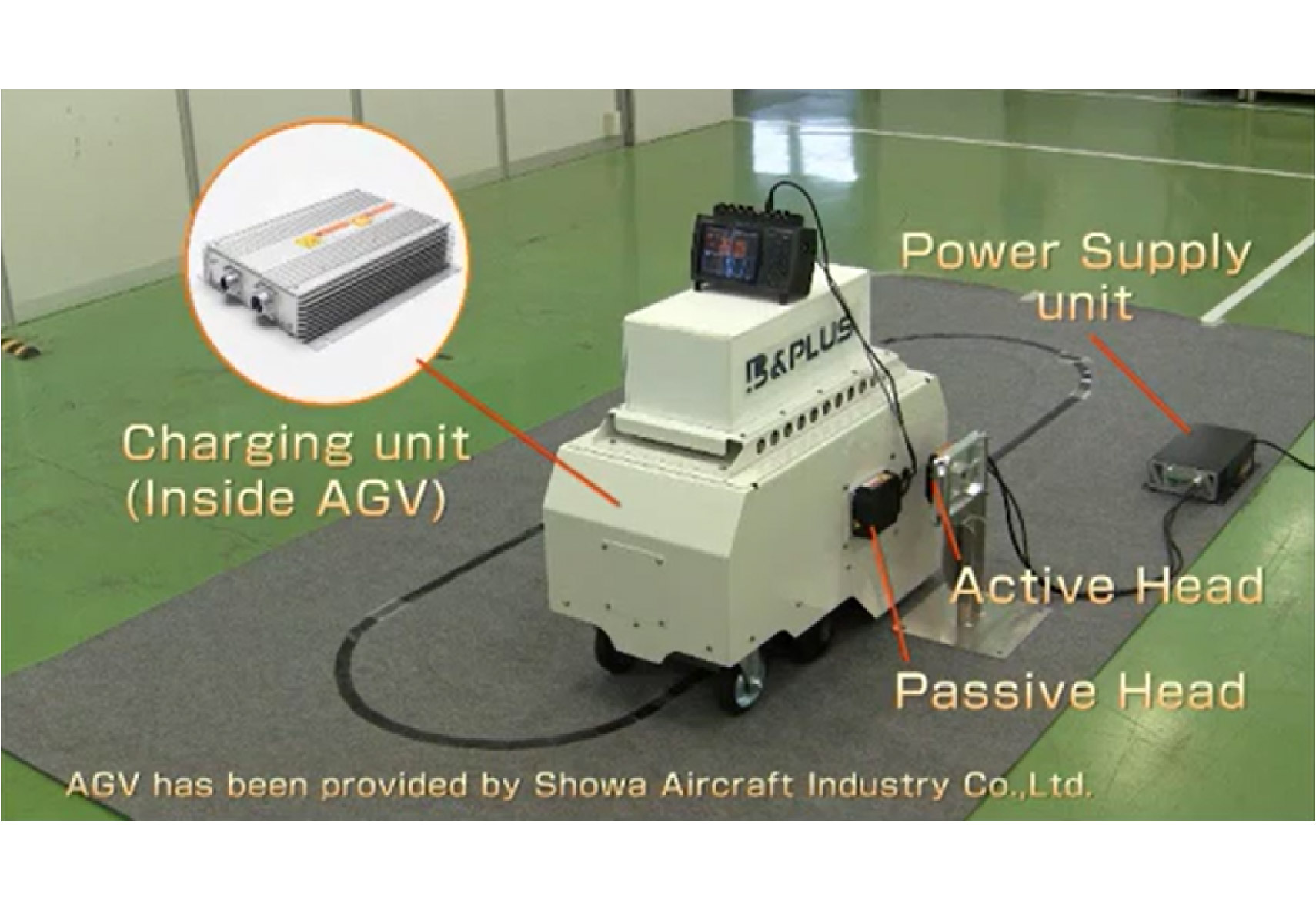

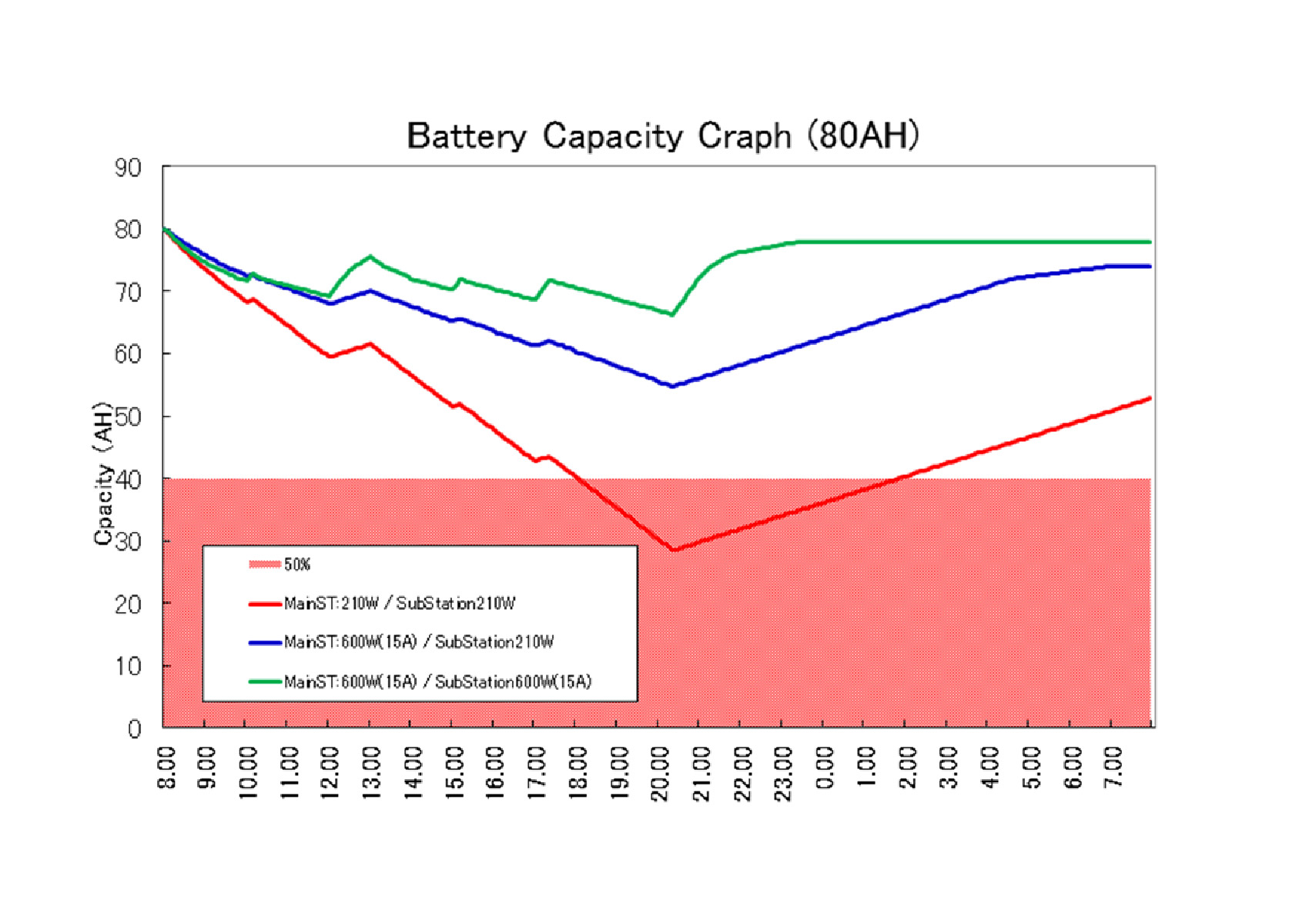

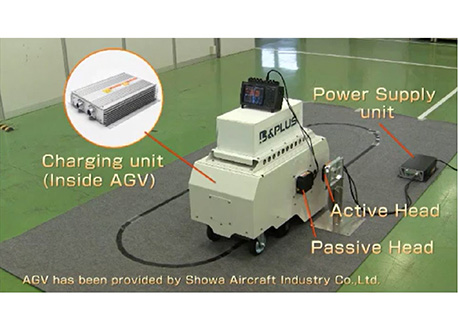

Contactless Charging System for AGV

It's a system that charges batteries of AGV (automated guided vehicle) automatically and without contact, which reduces battery replacement time and problem that may occur to the operator.

-

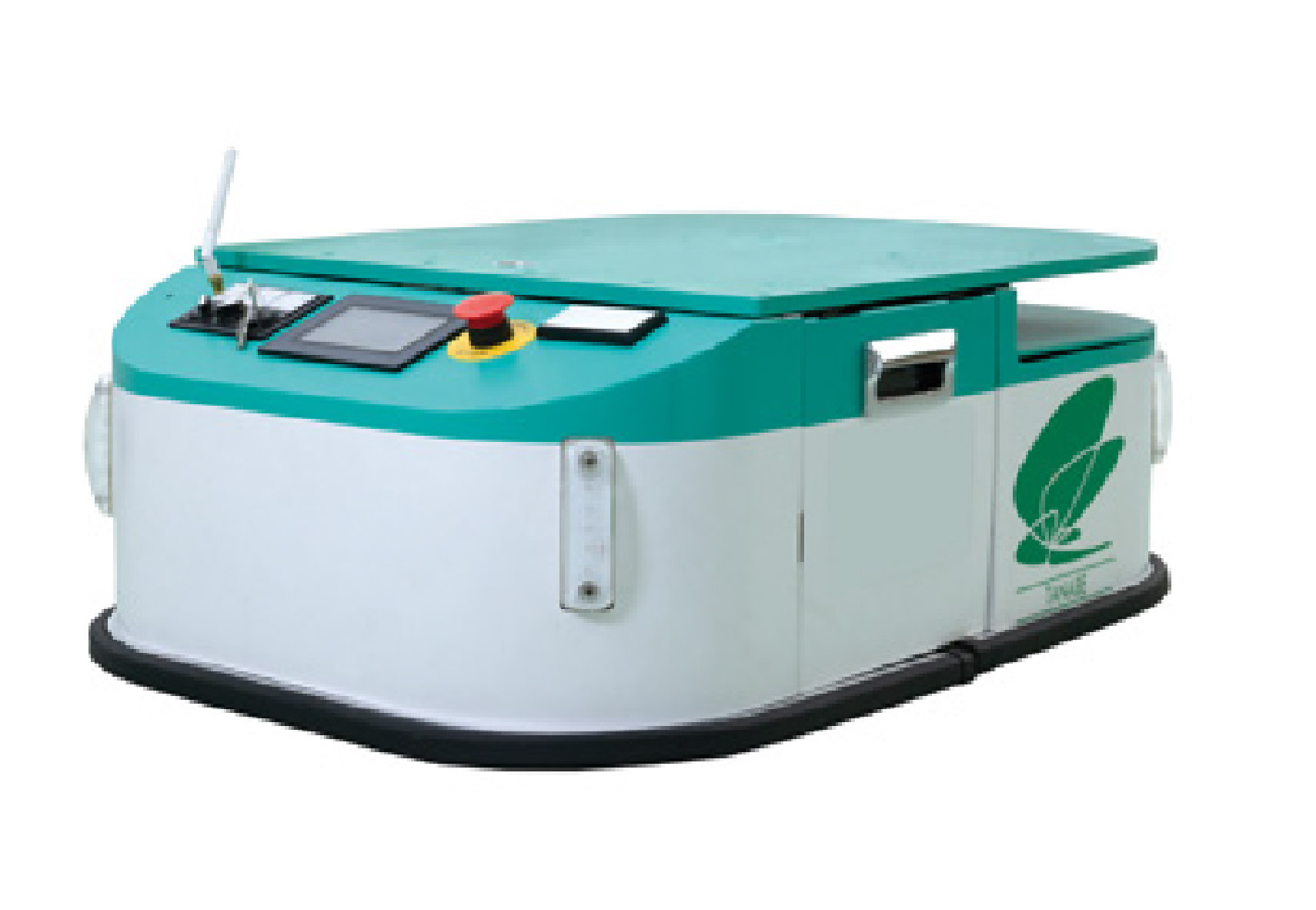

Trackless AGV

AGV can be used without using magnetic tape as tracks, realizing unmanned transport system that loads and unloads automatically.

-

Automatic Inventory

As overhead spaces are used more effectively, overall area use can be significantly reduced. And since inventory status can be managed by the system, excessive inventory and time required to manage inventoryy can be reduced.

-

Solar Power systems

By using the power generated by the solar cell system, we can significantly reduce CO2 and power costs. Panel life are guaranteed for 25 years. And by applying for BOI, which we also do it for you, you can further reduce the investment amount.

-

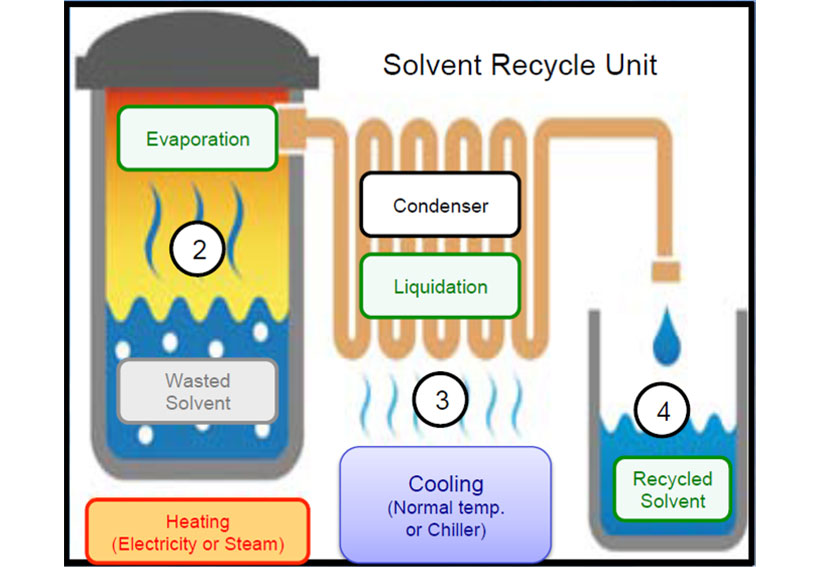

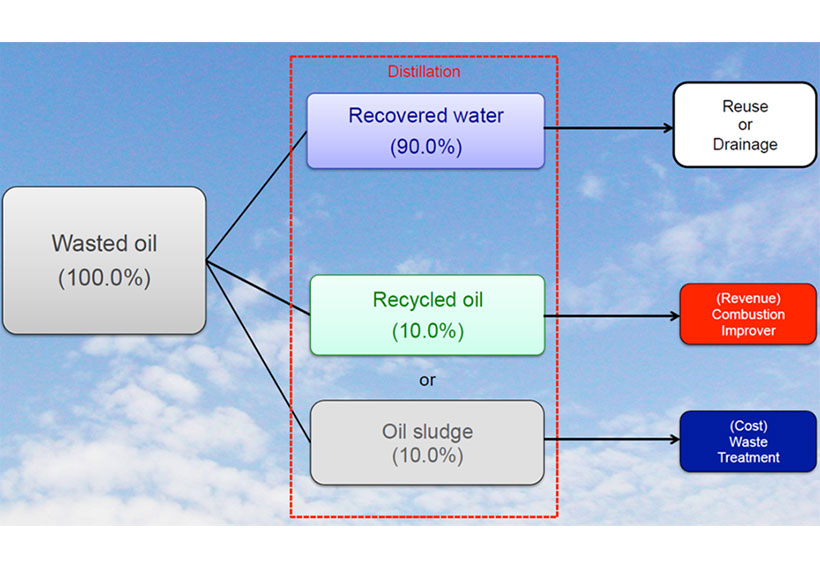

Waste Oil Recycling

By recovering useable elements from used coolant, dependency on external subcontractors can be reduced.

-

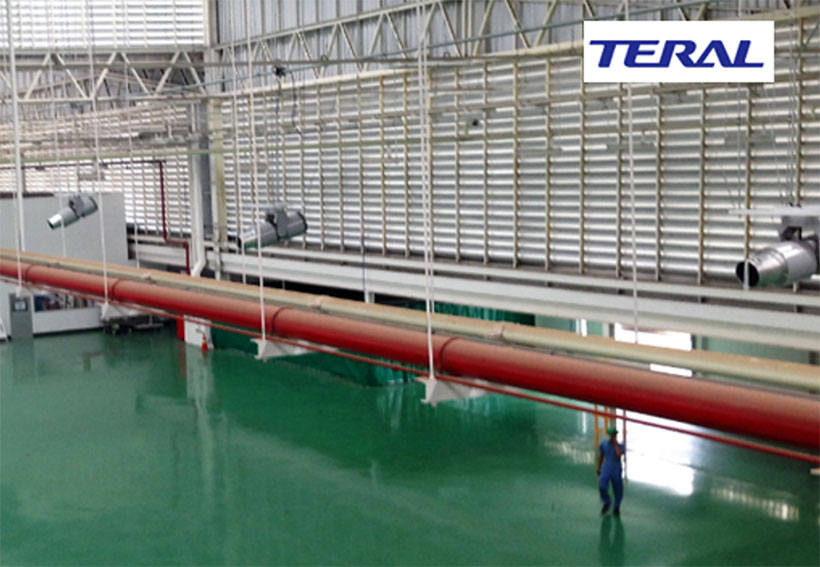

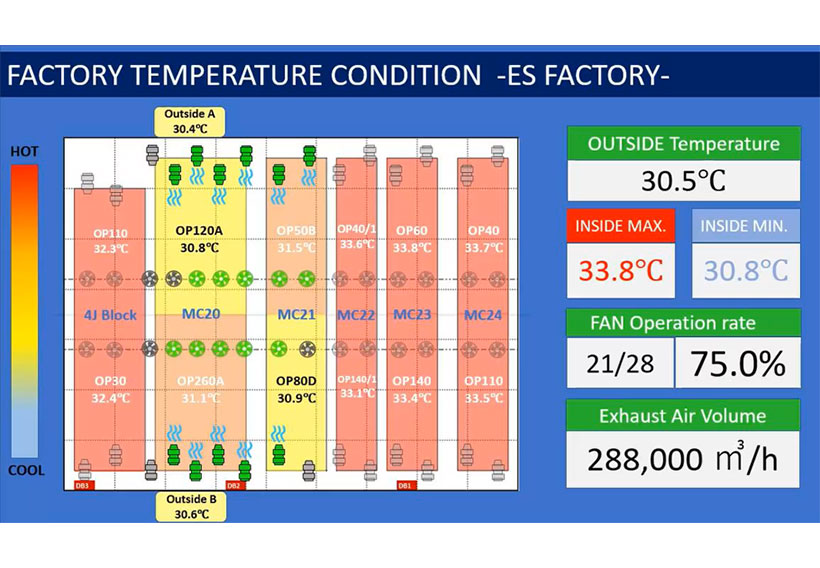

Industrial Blower

Temperature inside the factory can be reduced more effectively by taking in cool air and eject out hot air,. Initial cost and power consumption are also substantially lower compared to air conditioning systems.

-

Air Compressor & Integrated Control System

By knowing the air consumption in the factory, multiple compressors can be operated more efficiently.

-

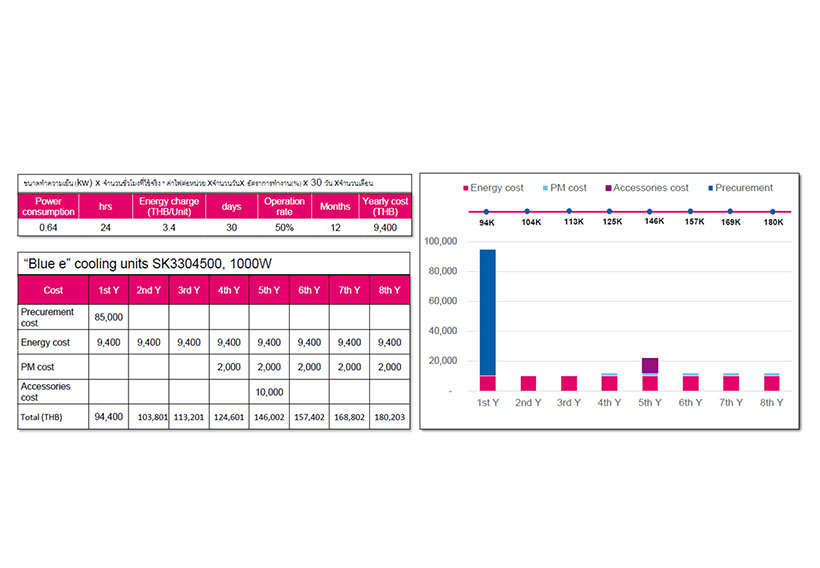

Cooler for Electric Control Panels

Prevents control panel failure due to heat. With compressor operation controlled by temperature, we can expect a maximum energy saving up to 75%.

-

Lubricant

Metal with this special type of lubricant applied can be expected to have 7 to 11 times longer life on average when compared with normal lubricants and same frequency of application, resulting in substantial reduction in cost of parts.

-

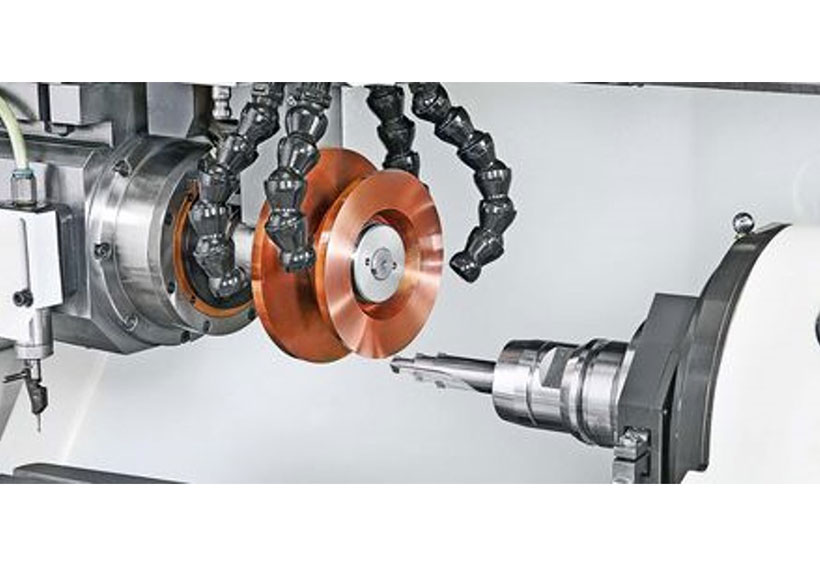

Cutting Tools and Cutting Tool Grinders

We are experts in handling both standard and special tools, making proposals for process improvement and tool cost reduction by profession.

Contactless Charging System for AGV

It's a system that charges batteries of AGV (automated guided vehicle) automatically and without contact, which reduces battery replacement time and problem that may occur to the operator.

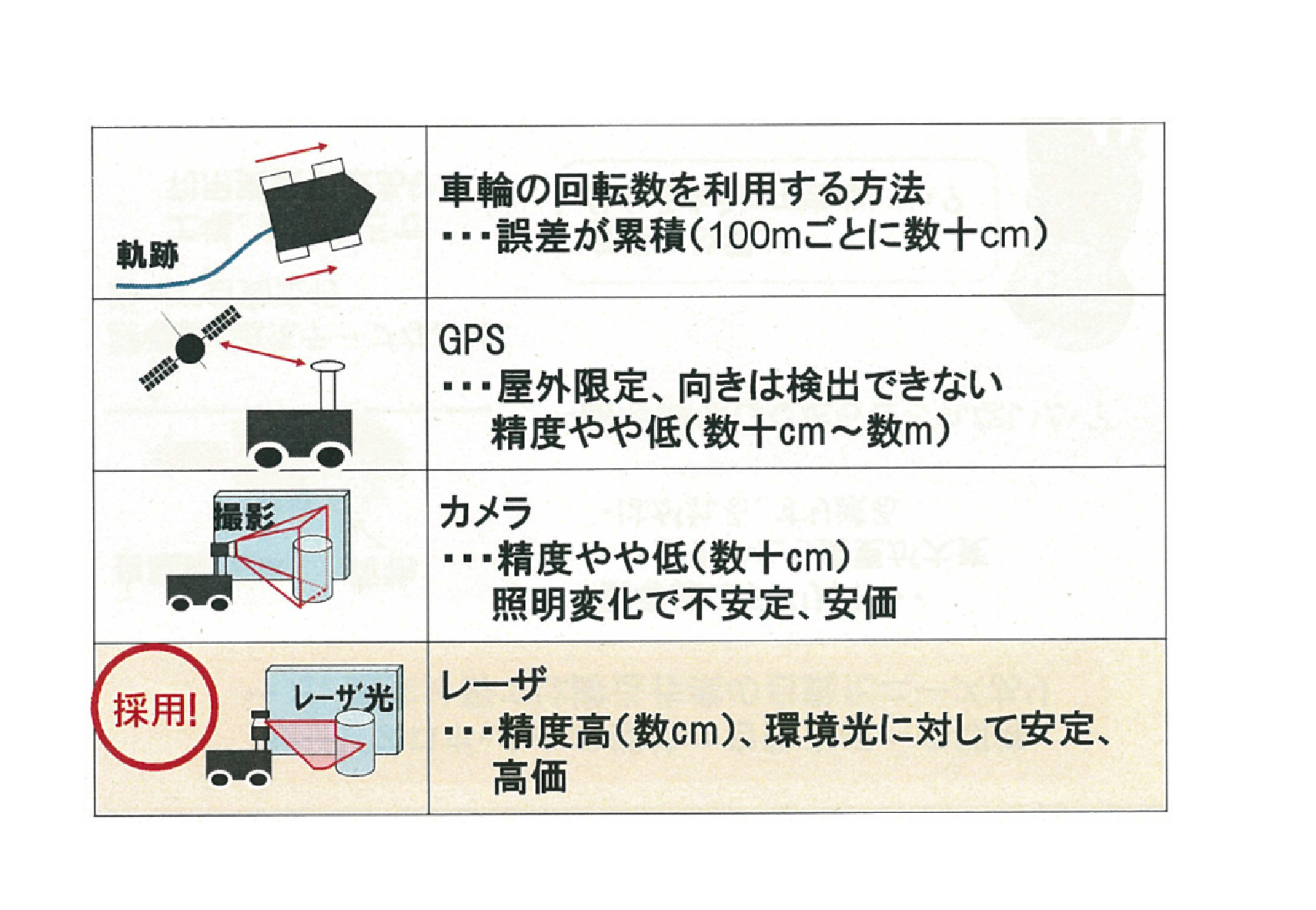

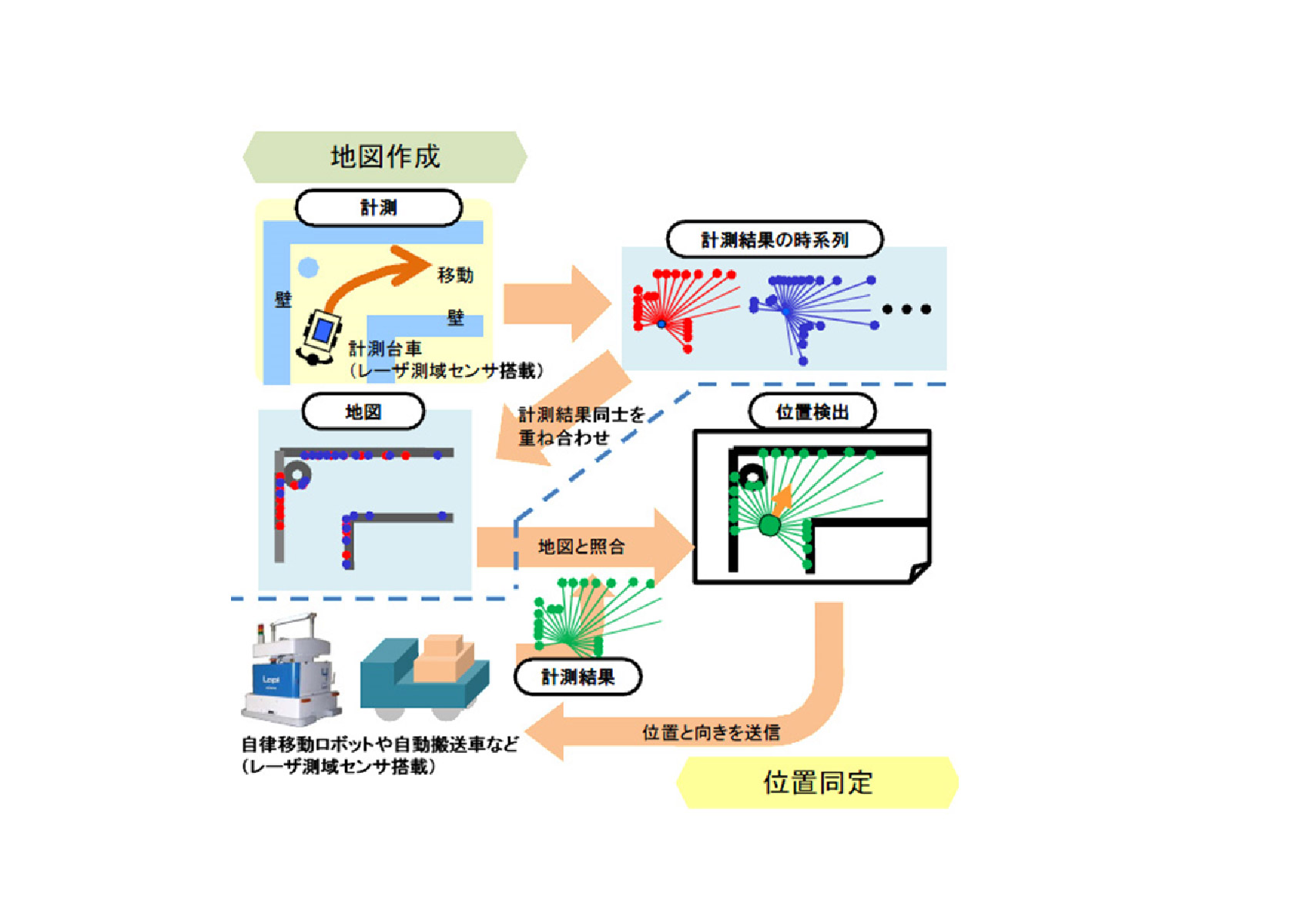

Trackless AGV

AGV can be used without using magnetic tape as tracks, realizing unmanned transport system that loads and unloads automatically.

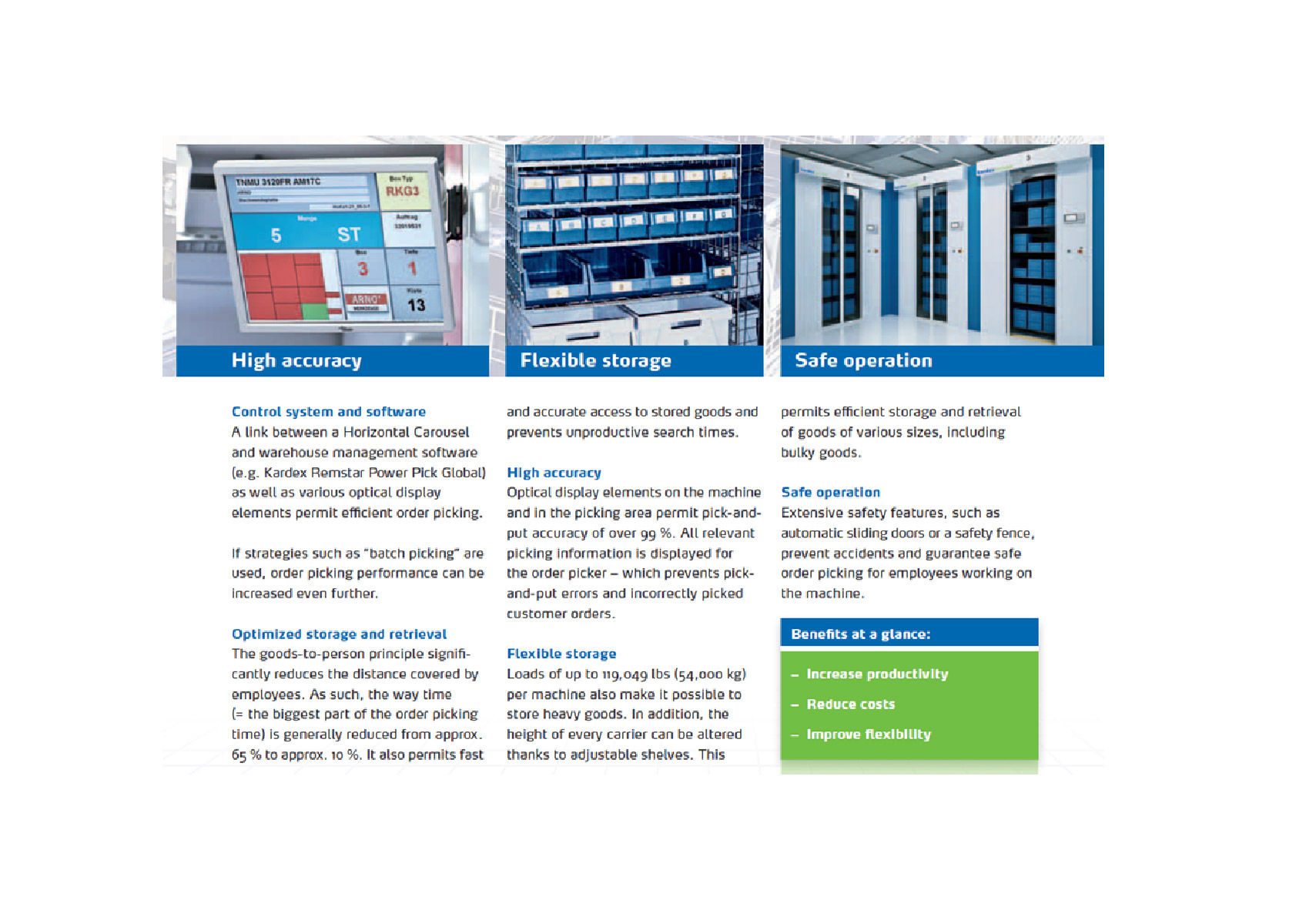

Automatic Inventory

As overhead spaces are used more effectively, overall area use can be significantly reduced. And since inventory status can be managed by the system, excessive inventory and time required to manage inventoryy can be reduced.

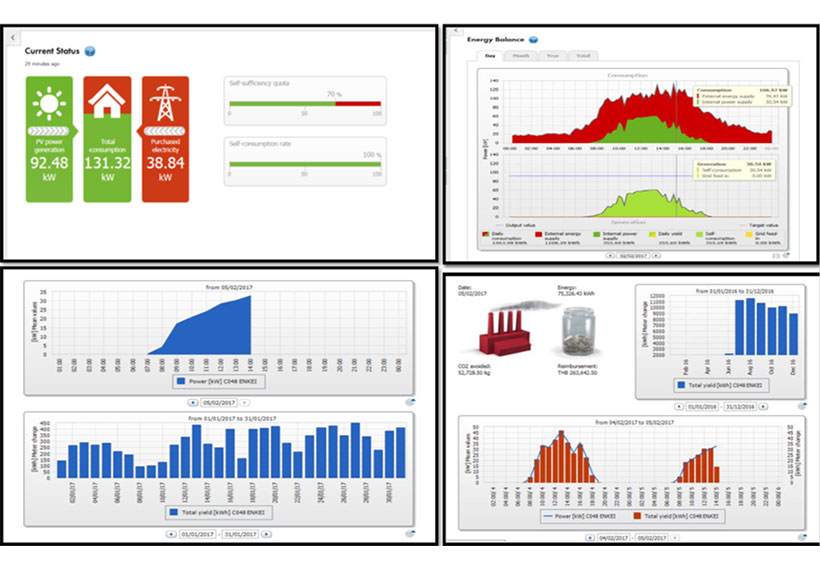

Solar Power systems

By using the power generated by the solar cell system, we can significantly reduce CO2 and power costs. Panel life are guaranteed for 25 years. And by applying for BOI, which we also do it for you, you can further reduce the investment amount.

Waste Oil Recycling

By recovering useable elements from used coolant, dependency on external subcontractors can be reduced.

Industrial Blower

Temperature inside the factory can be reduced more effectively by taking in cool air and eject out hot air,. Initial cost and power consumption are also substantially lower compared to air conditioning systems.

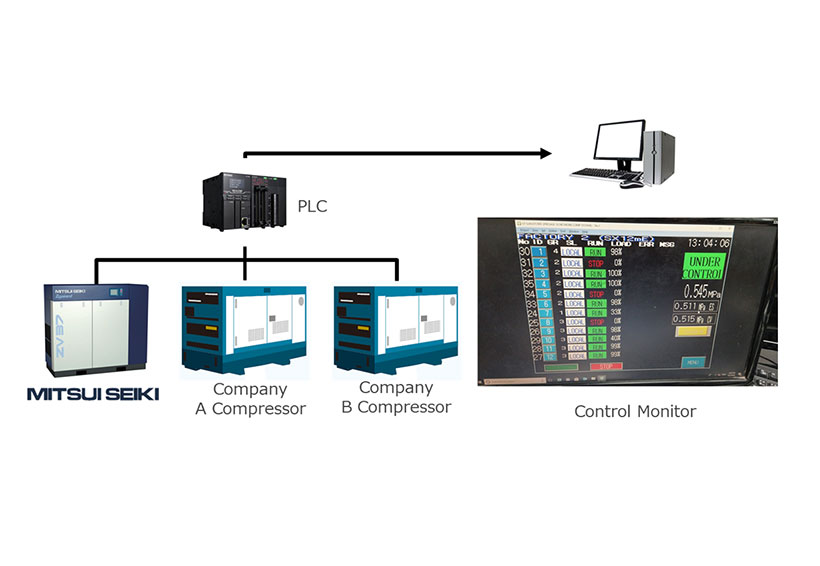

Air Compressor & Integrated Control System

By knowing the air consumption in the factory, multiple compressors can be operated more efficiently.

Cooler for Electric Control Panels

Prevents control panel failure due to heat. With compressor operation controlled by temperature, we can expect a maximum energy saving up to 75%. 。

Lubricant

Metal with this special type of lubricant applied can be expected to have 7 to 11 times longer life on average when compared with normal lubricants and same frequency of application, resulting in substantial reduction in cost of parts.

Safety Boots

With surface gripping strength more than 2.5 times of normal rubber, it shows surprising performance not only on normal roads, but also over oil, water, and other slippery surfaces.

Cutting Tools and Cutting Tool Grinders

We are experts in handling both standard and special tools, making proposals for process improvement and tool cost reduction by profession.

Construction & Engineering

-

Tent Warehouse

Tent Warehouse using Membrane material realizes a comfortable space at low cost.Moreover, since expansion and relocation can be done in a short period of time, it is possible to fully utilize the land according to future designs.

-

Tent Products

We build Canvas Roof such as Loading Area Roof,Walkway Roof,Parking Roof, also Canvas Room inside Factory & Jabara Curtain etc.

-

Uniflow Door Products

We are an authorized distributor of Uniflow products. Highly airtight High-Speed Sheet Shutter "Jetter" and "Smoother with excellent wind resistance," Self-Closing Swing Doors and PVC Curtains.

-

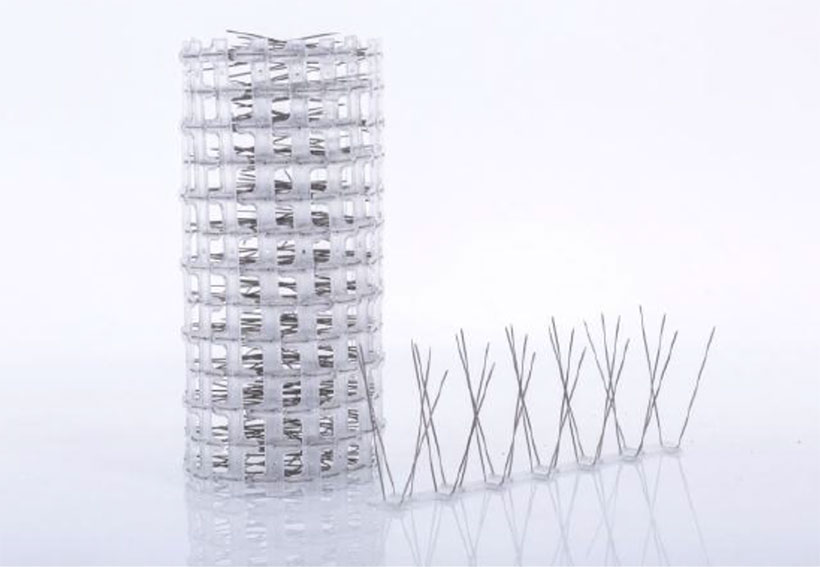

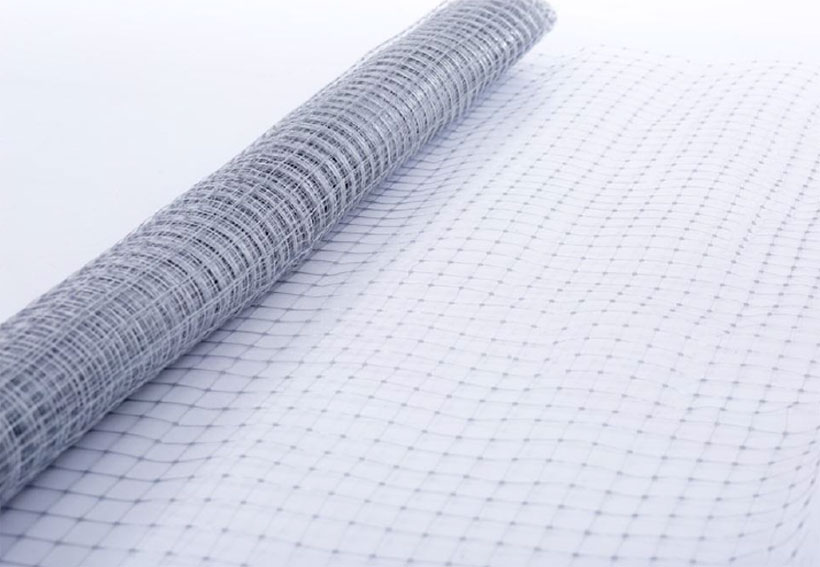

Bird Protection

Problems caused by birds in factories can be inexpensively addressed.

-

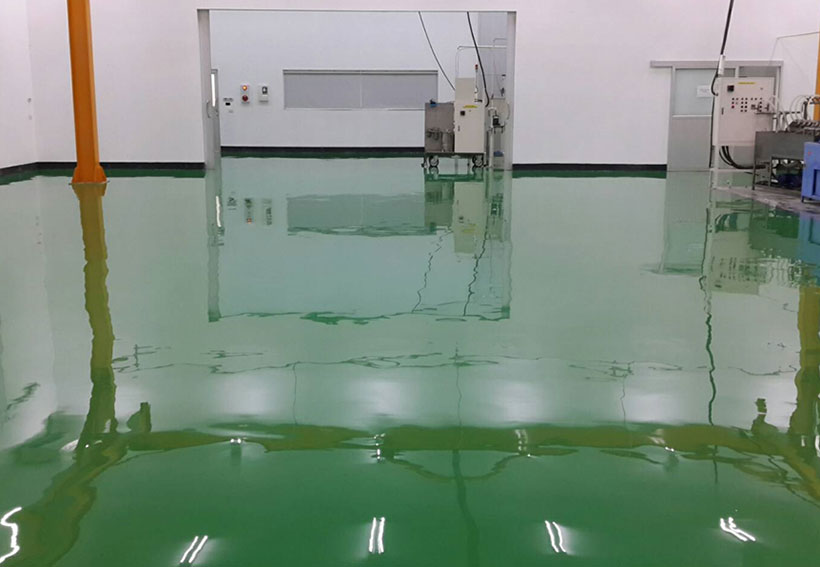

Floor Coating

Due to it being inexpensive and can be carefully constructed with no unevenness on the surface, floor coating can last a long time without damage even if a forklift or other transport vehicles are driven over it.

Tent Warehouse

Tent Warehouse using Membrane material realizes a comfortable space at low cost.Moreover, since expansion and relocation can be done in a short period of time, it is possible to fully utilize the land according to future designs.

Bird Protection

Problems caused by birds in factories can be inexpensively addressed.

Floor Coating

Due to it being inexpensive and can be carefully constructed with no unevenness on the surface, floor coating can last a long time without damage even if a forklift or other transport vehicles are driven over it.

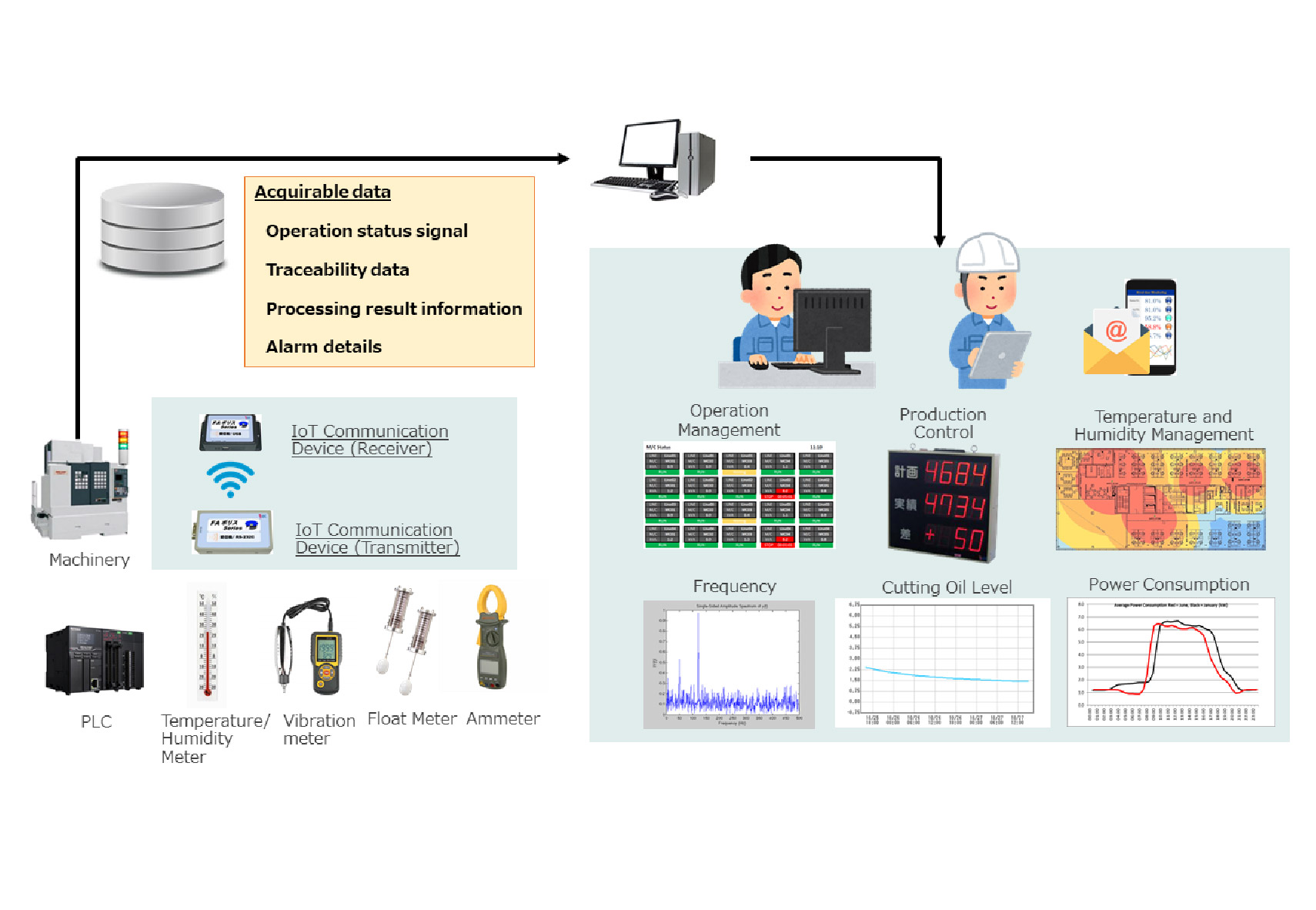

IoT / AI

-

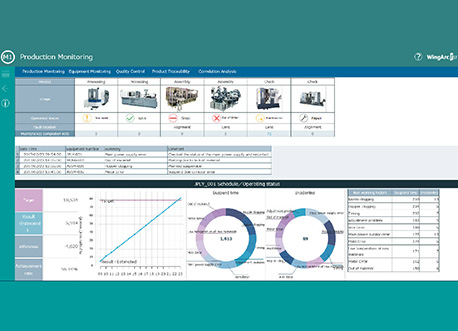

Centralized management system

Various information such as the operation status of machinery and equipment, abnormal signals, temperature and humidity, power consumption, and frequency can be acquired.

-

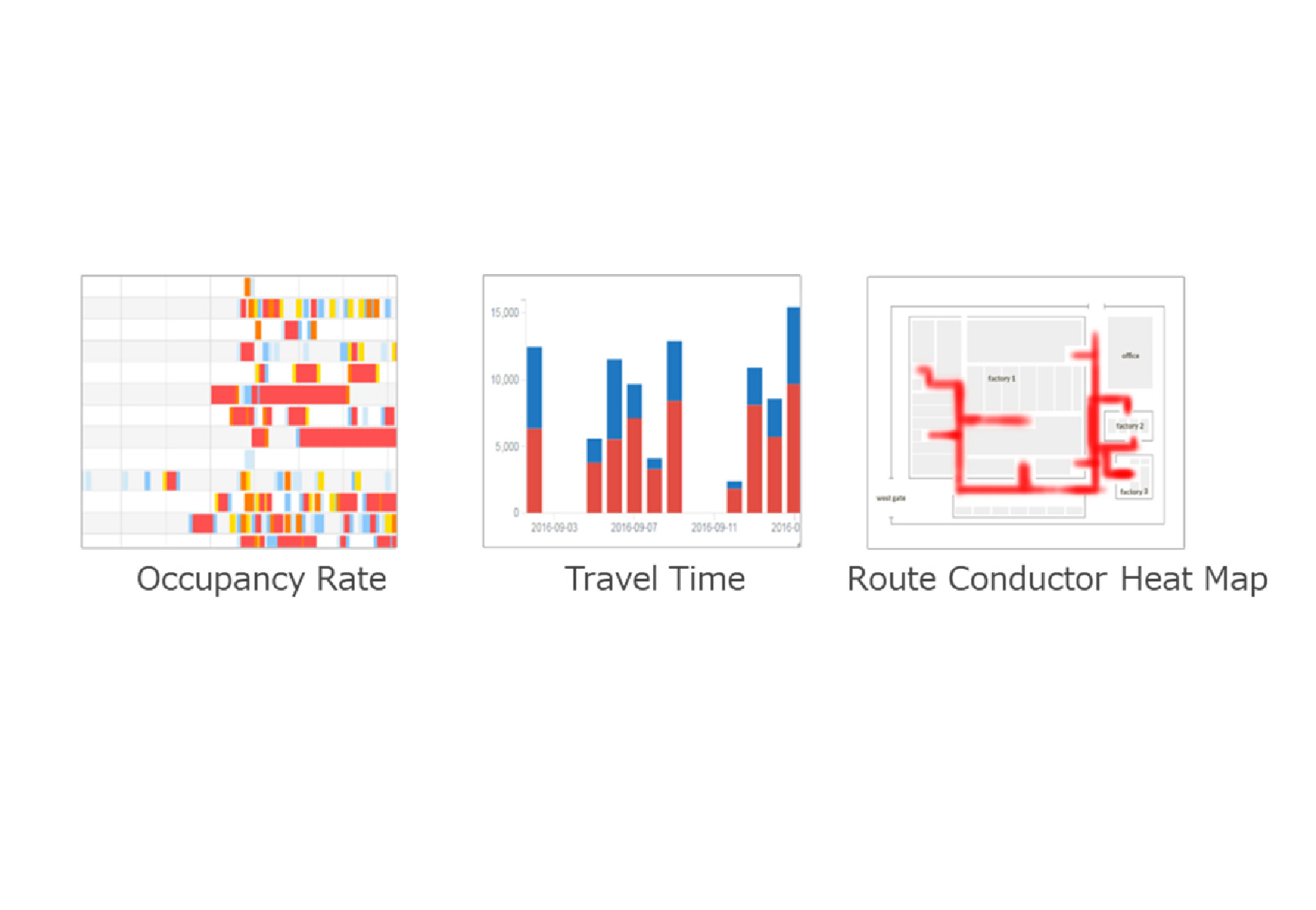

Visualization analysis tool

The data accumulated by visualization can be viewed in real time on a personal computer, and can also be used as a report that can be used in meetings.

-

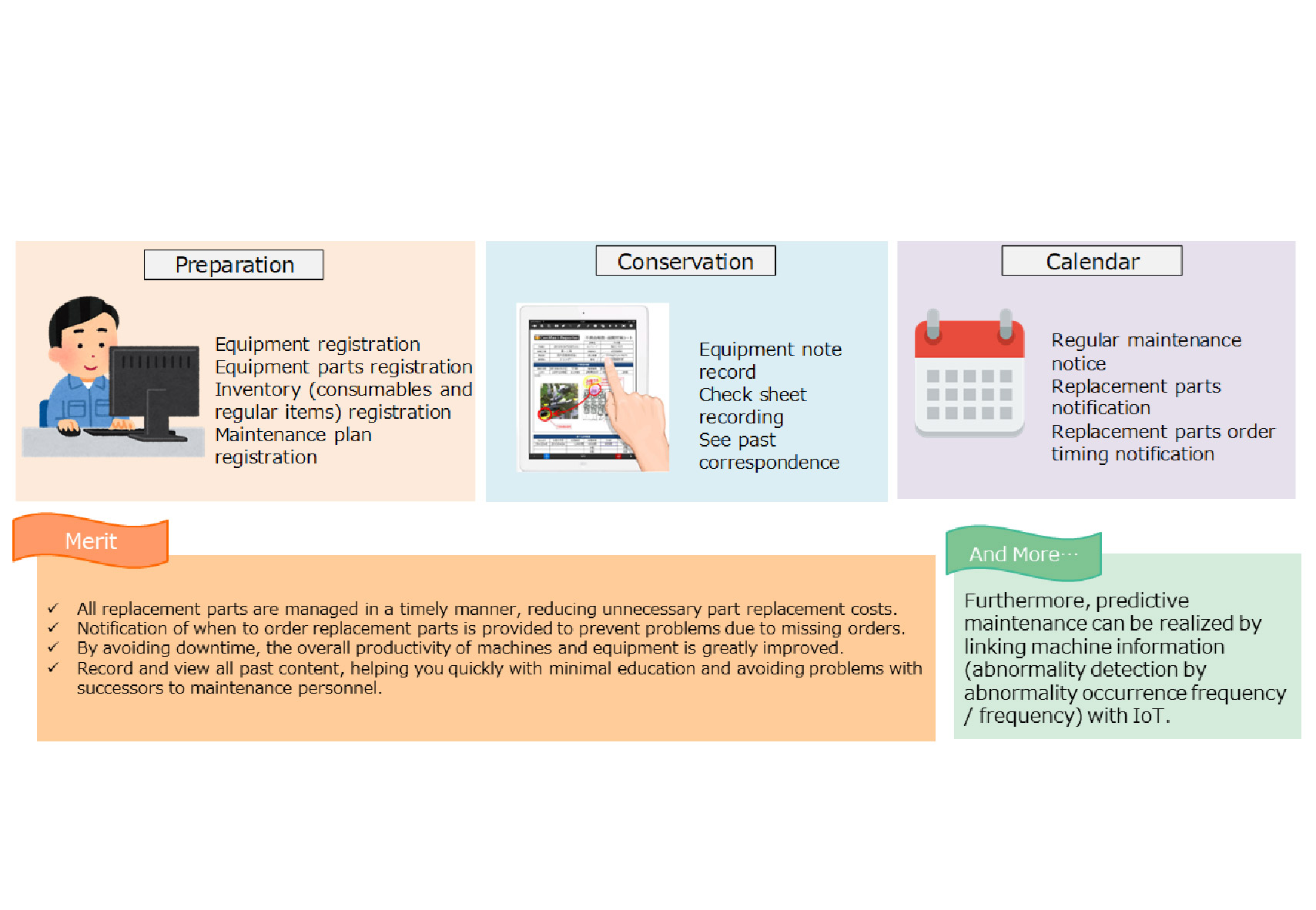

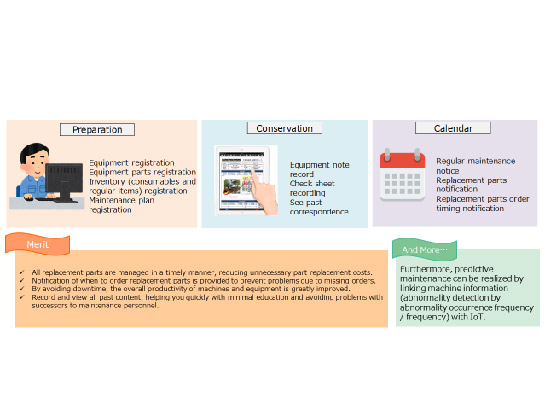

Maintenance system

By using a tablet to record daily maintenance activities, user can share the content immediately. By registering, life of parts can be estimated, which enables user to calculate appropriate time to order spare parts.

-

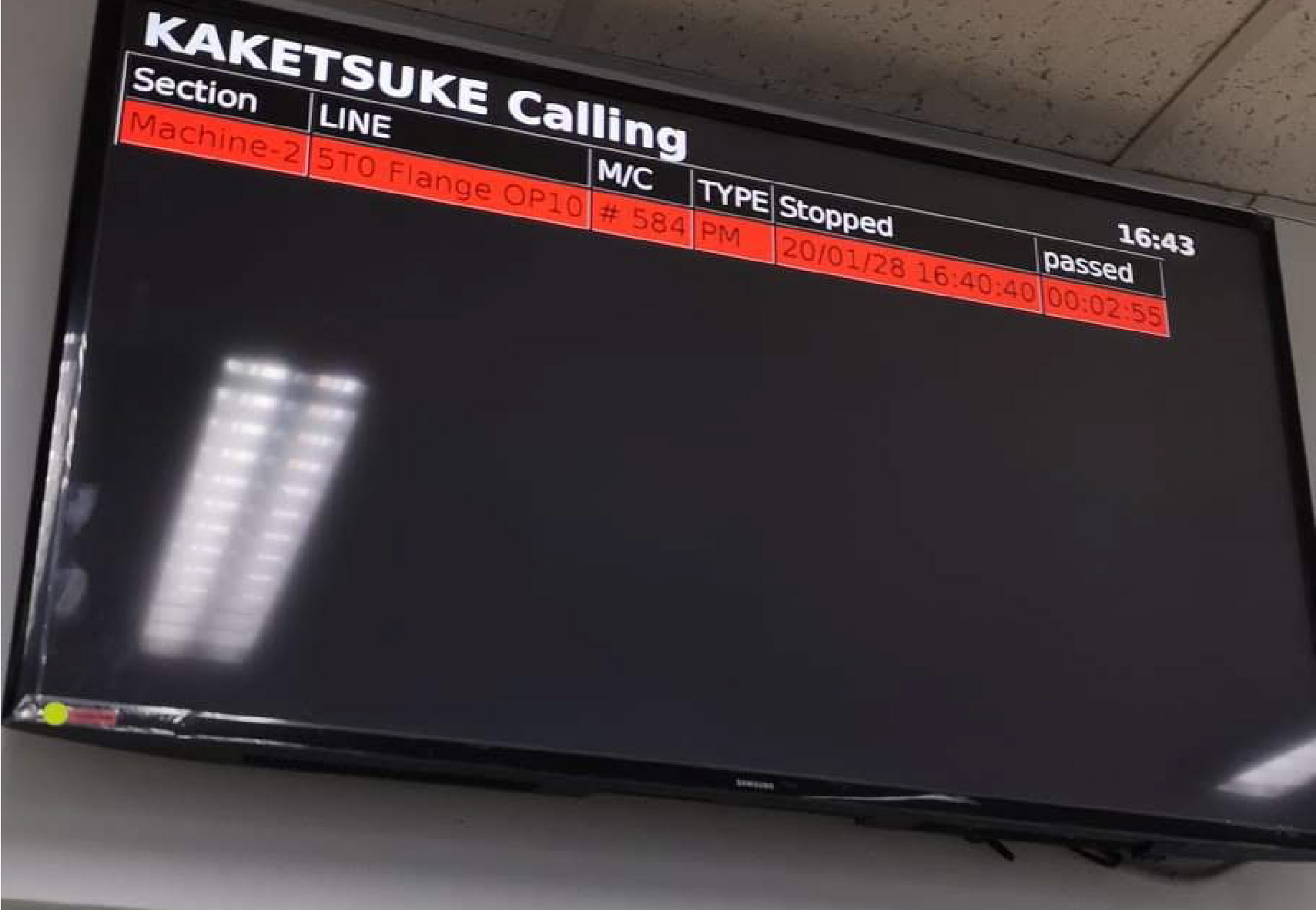

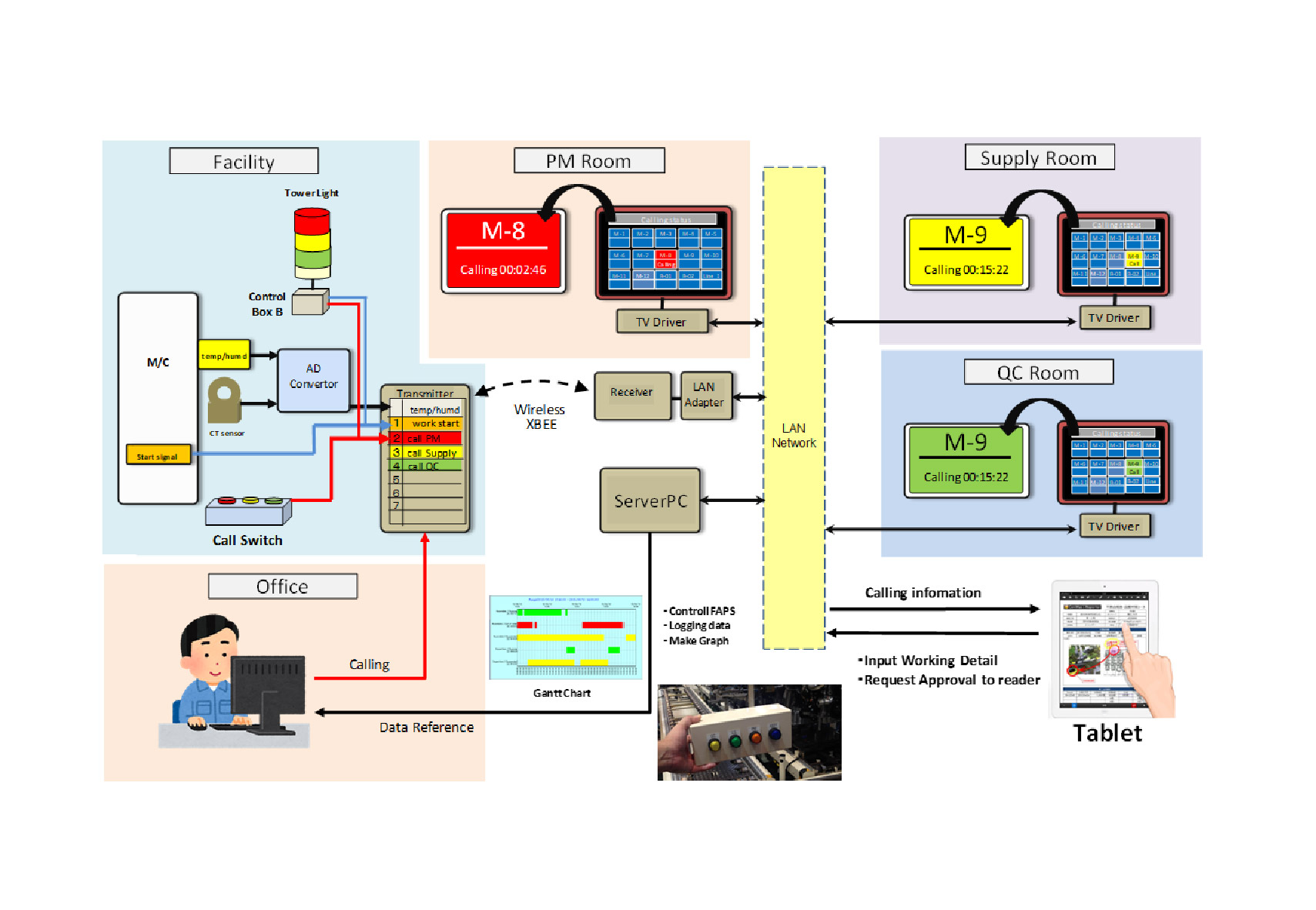

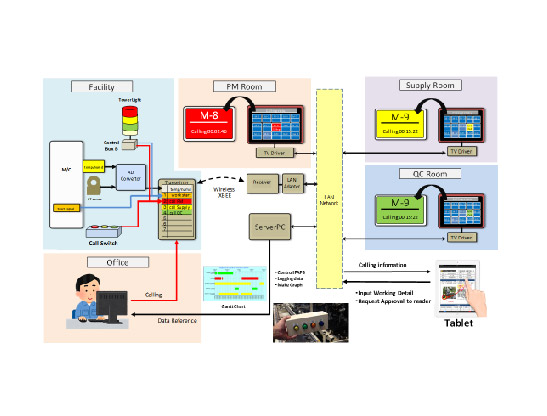

Call system

Problems that occur on site can be quickly reported to the relevant departments. By transmitting error information that has occurred in the equipment, relevant departments can prepare appropriate equipments and head to the site.

-

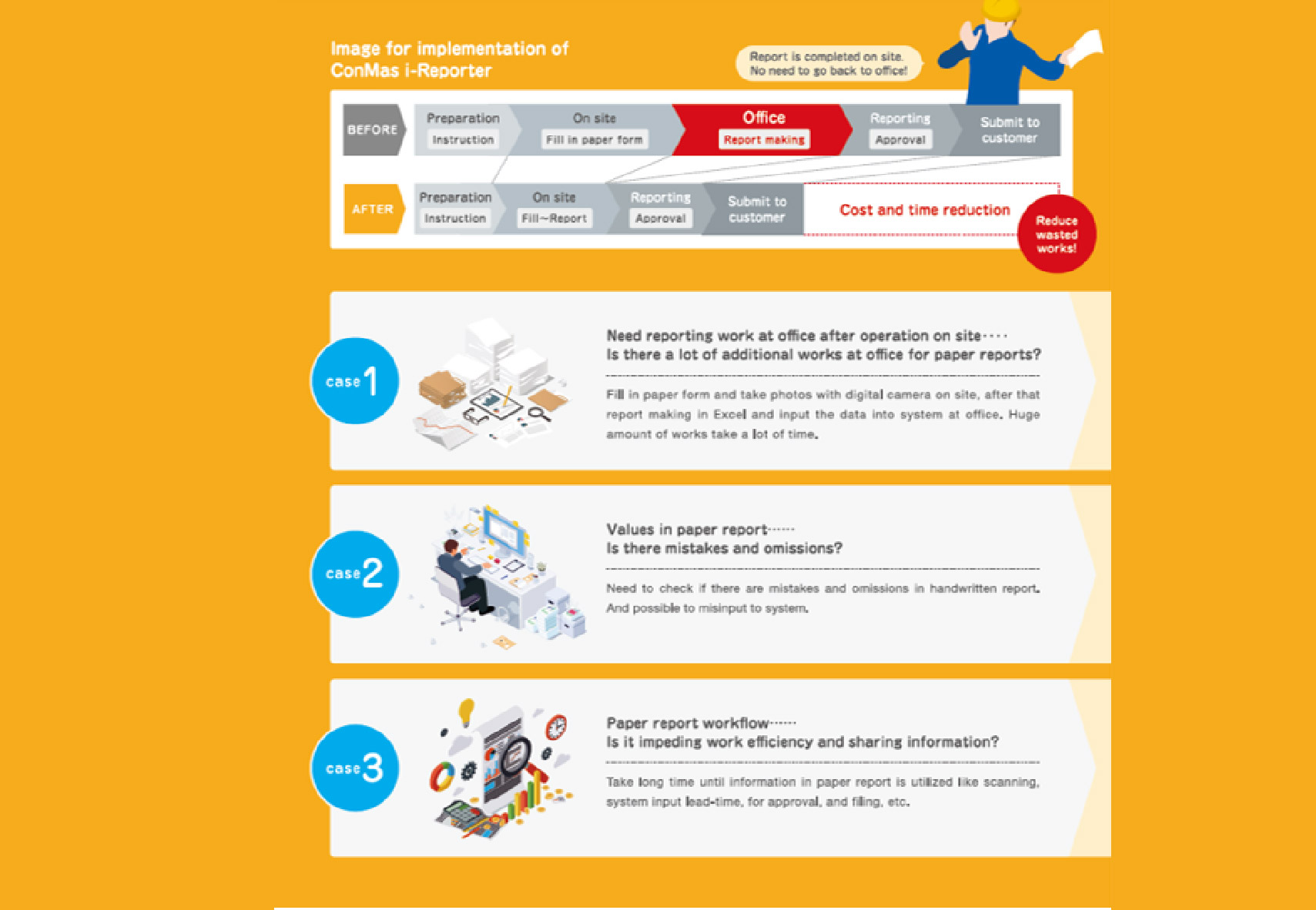

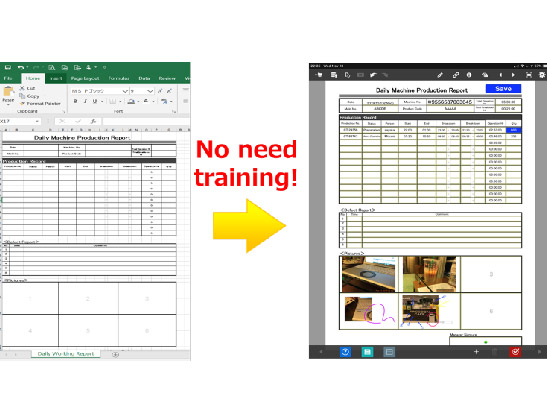

Electronic report system

Paper forms and Excel forms that are routinely used can be converted to digital format without changing anything. Forms entered can be quickly digitized, eliminating the need for data entry at the office. This way, costs of management, printing, and overtime can be reduced.

-

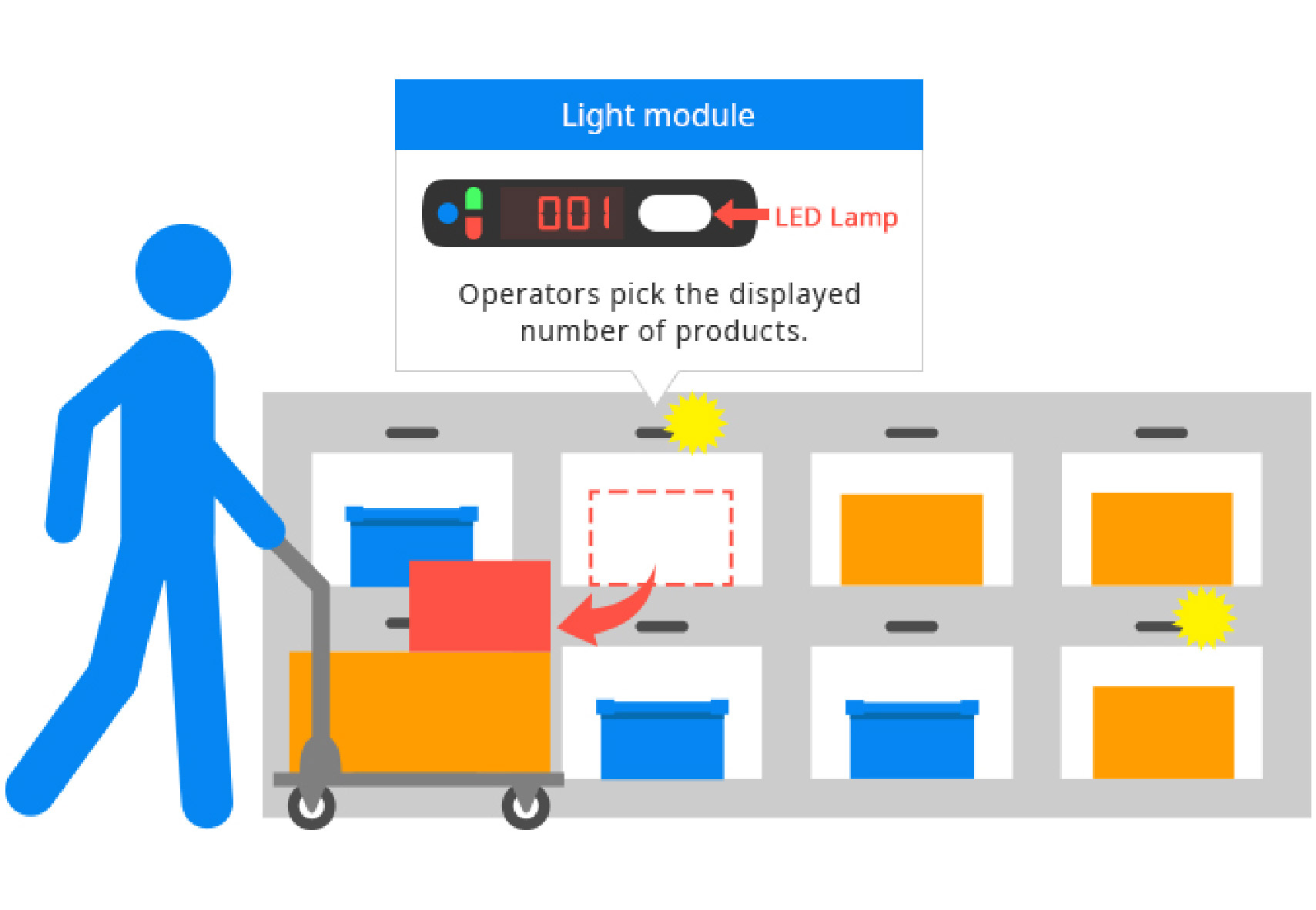

Digital picking system

By supporting the picking of parts, this system can eliminate waste and error of workers and improve work efficiency.

-

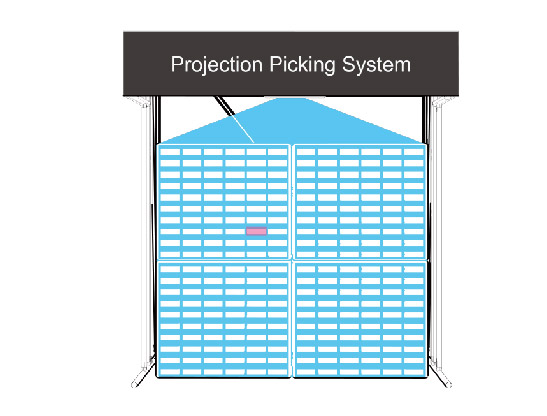

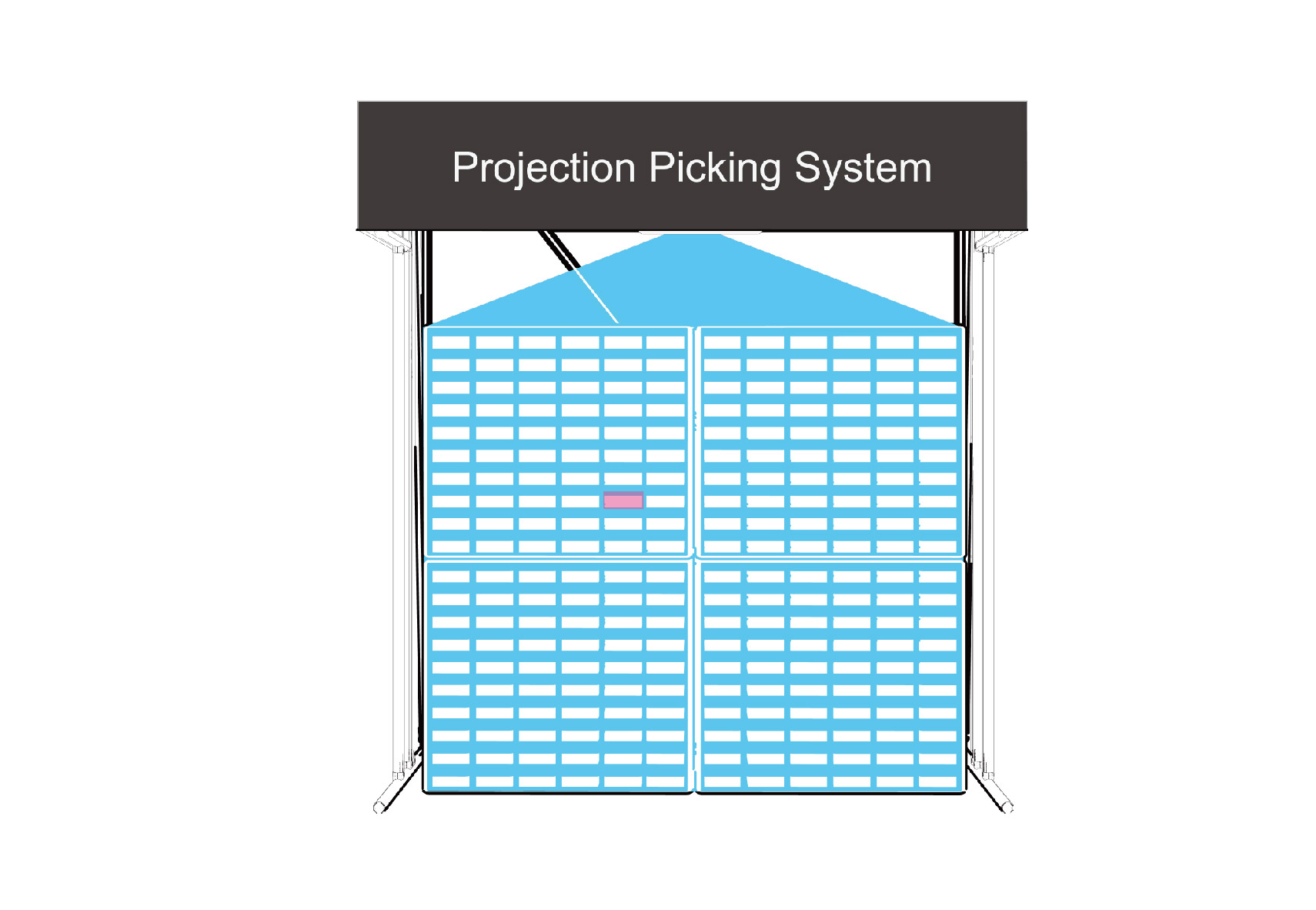

Projection picking system

It is a picking system that can be flexibly constructed according to shelves and racks of various shapes by applying image processing technology. It also has a "Pokayoke" function, which supports picking work from factory assembly lines and distribution centers. This system can also be installed in places where the display could not be mounted.

-

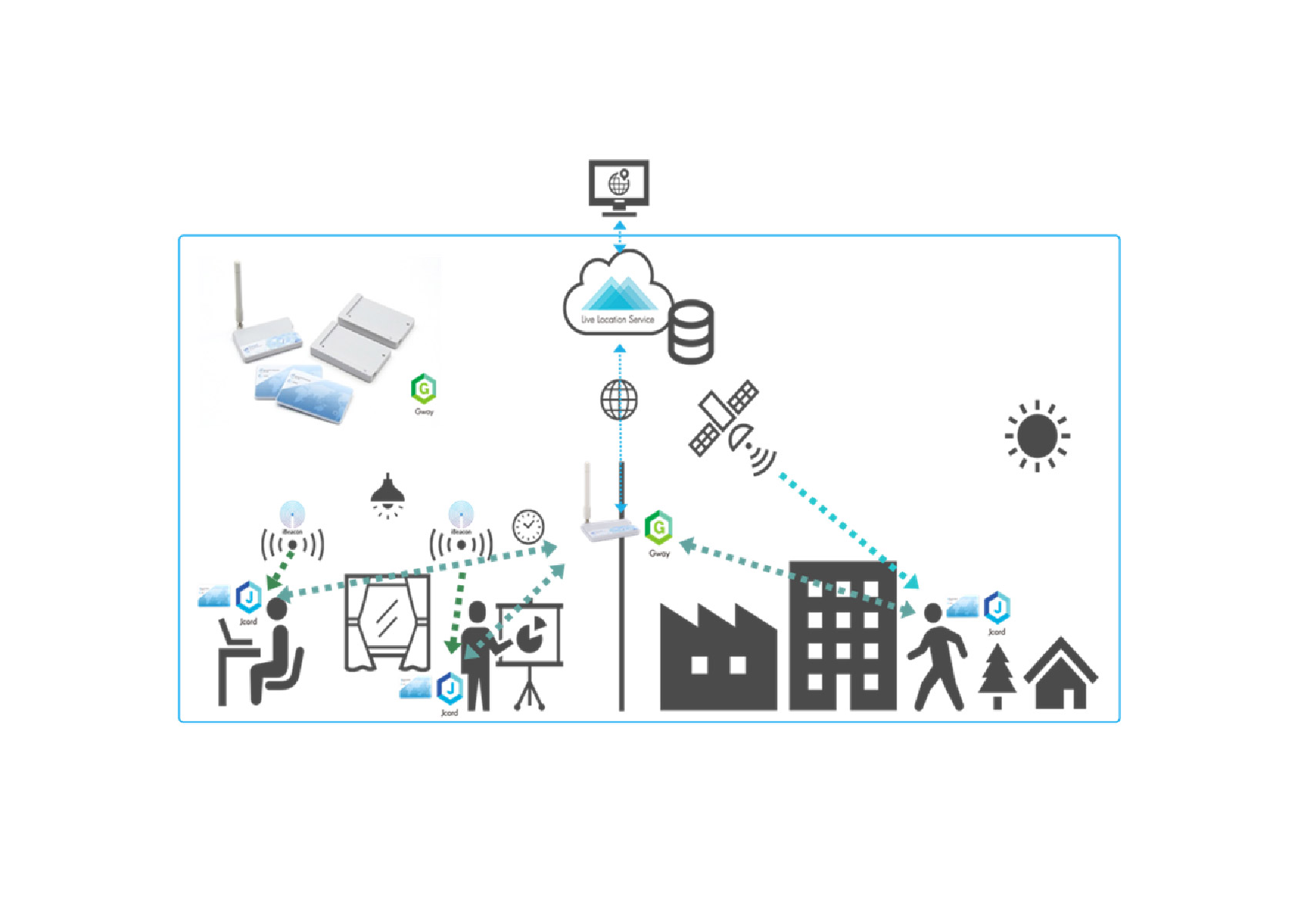

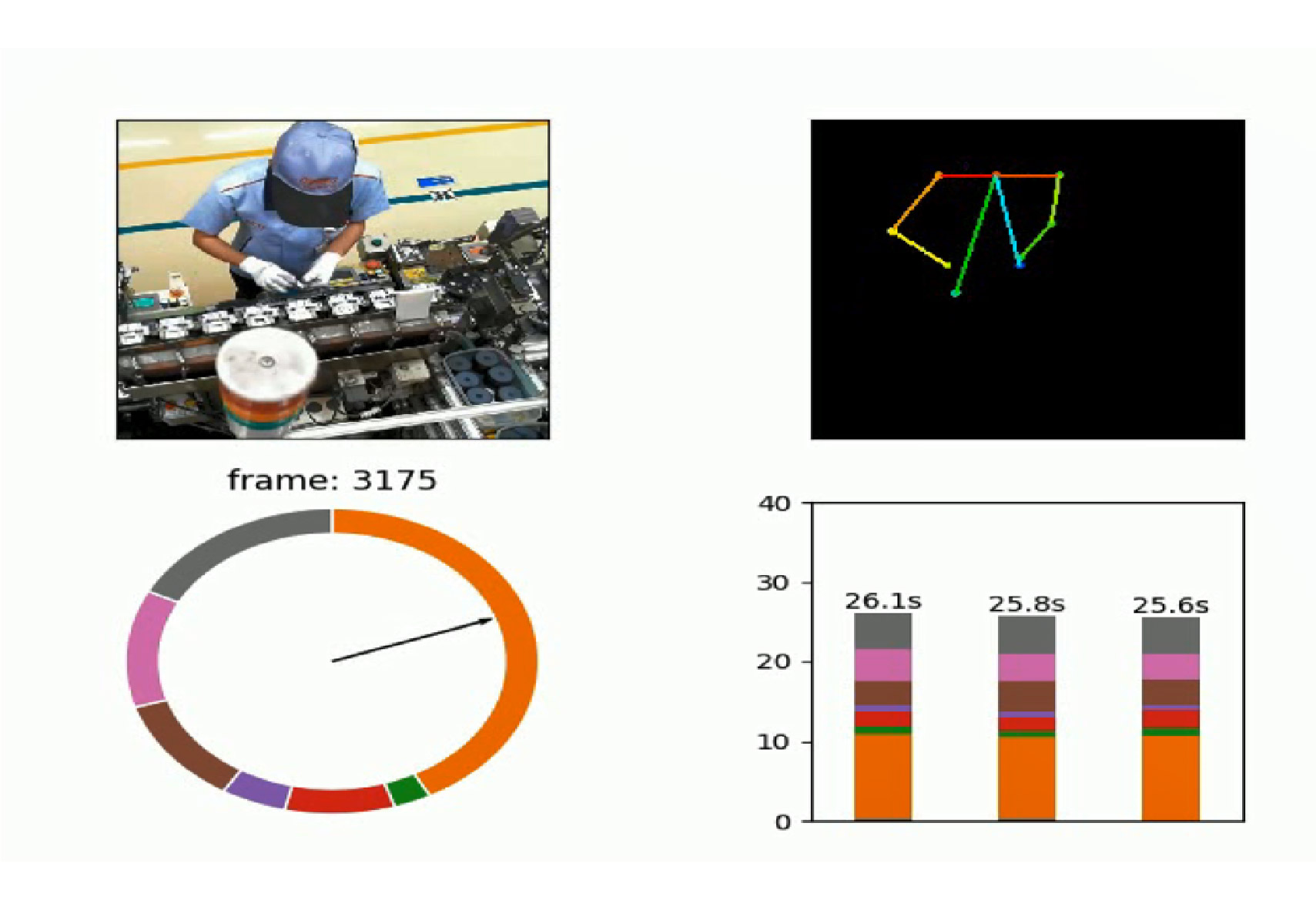

Live Location Service

By measuring the position information of workers and forklifts, it is possible to improve the efficiency of material flow lines.

-

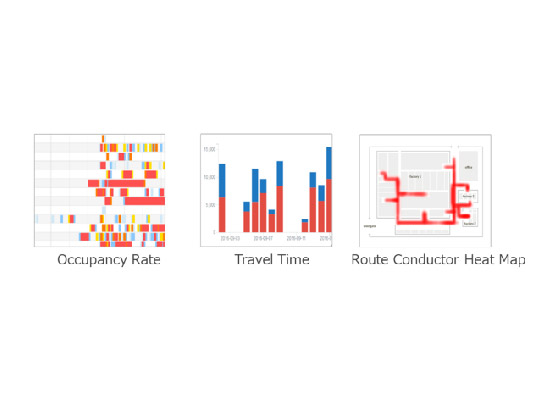

AI

The AI system os specially made for manufacturing industry. By learning the movement of the worker recorded by the camera using AI, it is possible to prevent worker's error.

IT(IoT/AI)

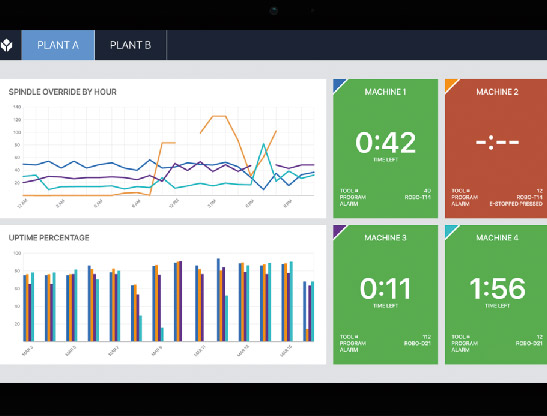

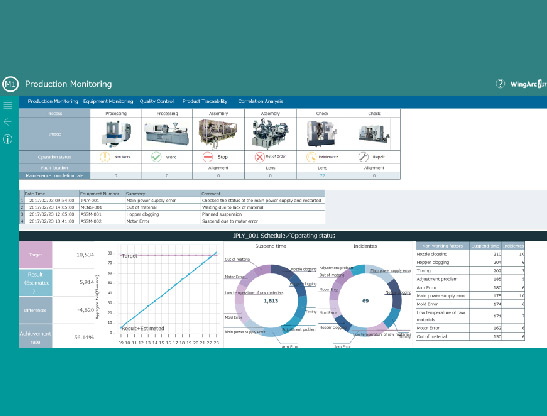

Centralized management system

Various information such as the operation status of machinery and equipment, abnormal signals, temperature and humidity, power consumption, and frequency can be acquired.

IT(IoT/AI)

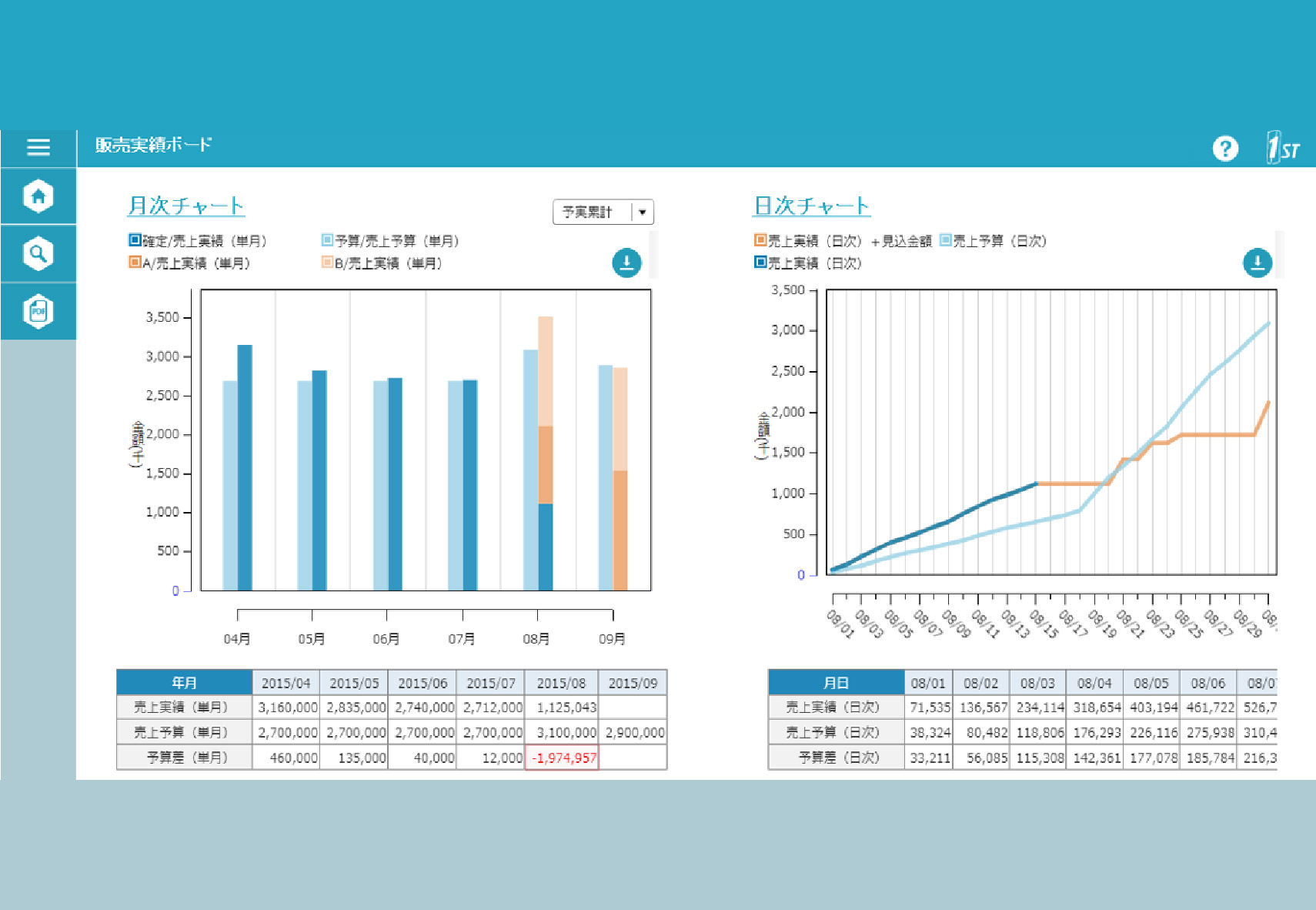

Visualization analysis tool

The data accumulated by visualization can be viewed in real time on a personal computer, and can also be used as a report that can be used in meetings.

IT(IoT/AI)

Maintenance system

By using a tablet to record daily maintenance activities, user can share the content immediately. By registering, life of parts can be estimated, which enables user to calculate appropriate time to order spare parts.

IT(IoT/AI)

Call system

Problems that occur on site can be quickly reported to the relevant departments. By transmitting error information that has occurred in the equipment, relevant departments can prepare appropriate equipments and head to the site.

IT(IoT/AI)

Digital picking system

By supporting the picking of parts, this system can eliminate waste and error of workers and improve work efficiency.

IT(IoT/AI)

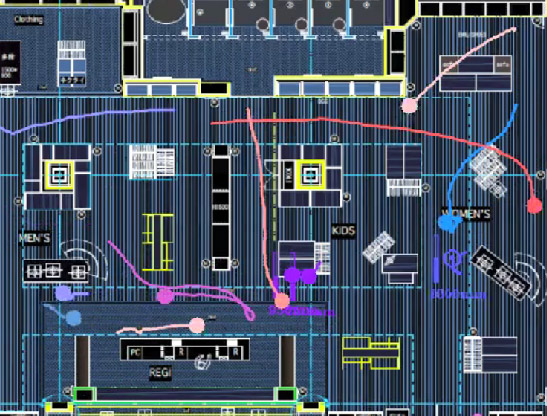

Live Location Service

By measuring the position information of workers and forklifts, it is possible to improve the efficiency of material flow lines.

IT(IoT/AI)

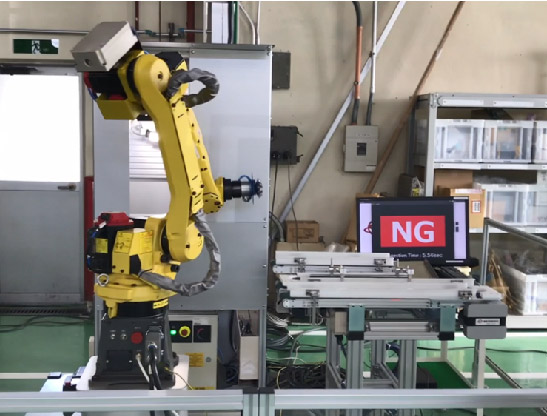

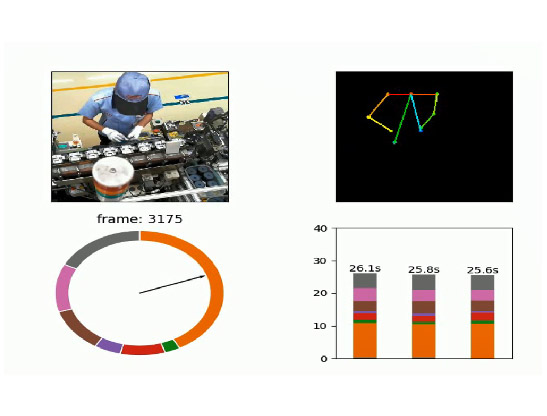

AI

The AI system os specially made for manufacturing industry. By learning the movement of the worker recorded by the camera using AI, it is possible to prevent worker's error.

IT(IoT/AI)

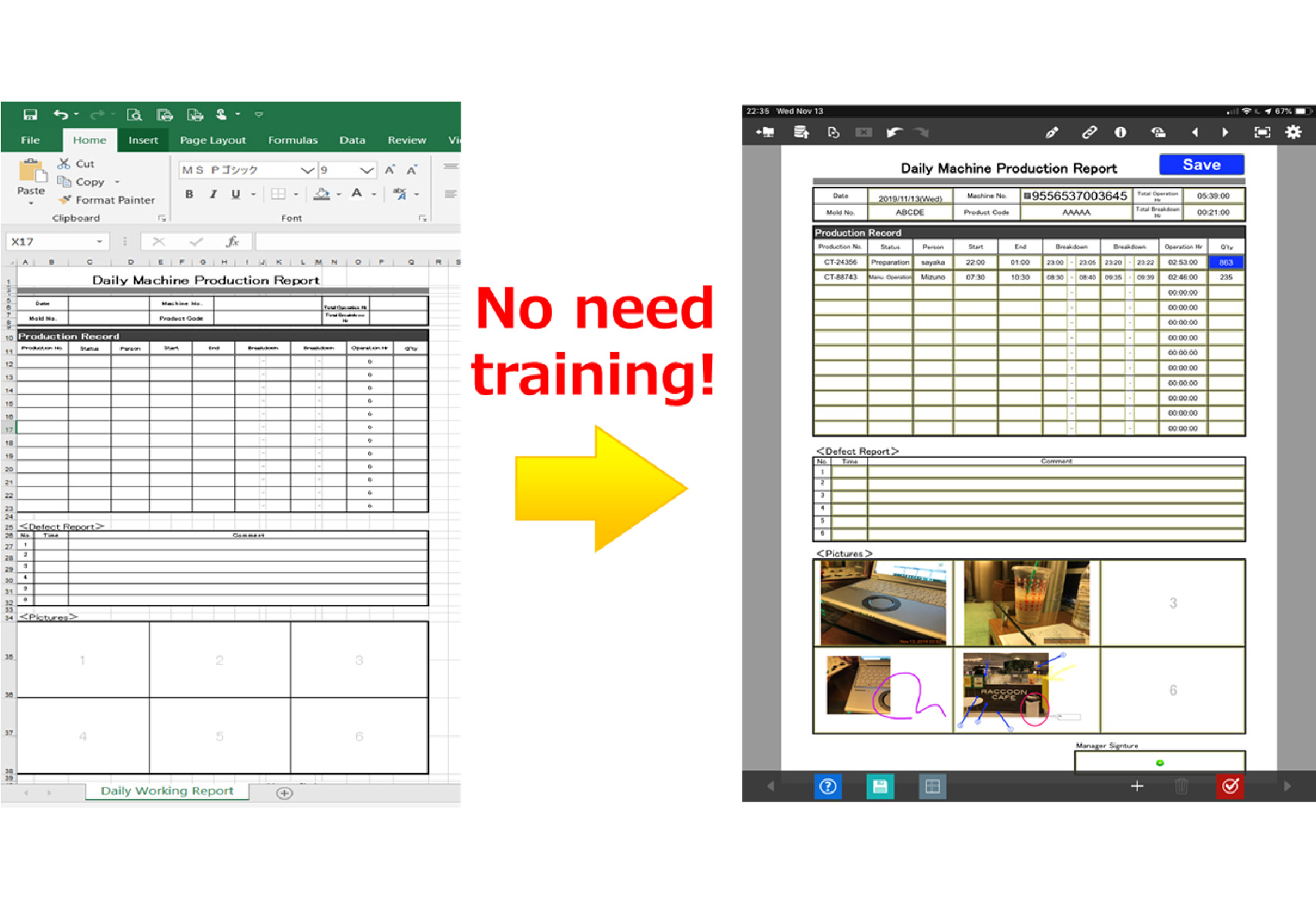

Electronic report system

Paper forms and Excel forms that are routinely used can be converted to digital format without changing anything. Forms entered can be quickly digitized, eliminating the need for data entry at the office. This way, costs of management, printing, and overtime can be reduced.

IT(IoT/AI)

Digital picking system

By supporting the picking of parts, this system can eliminate waste and error of workers and improve work efficiency.

Clients

Partners

CASE /01

IT (IoT / AI) centralized management system

IT(IoT/AI)

Usually, when machining time is long, the operator has to set the machine in automatic mode to stop automatically in the next day.

However, many times something unexpected happens, resulting in machining work not being completed as planned and work schedule being out of control.

By monitoring the operation status of the machine and notifying any error to the person in charge by e-mail, information regarding abnormalities became visible, enabling operator to promptly correct he problem. This leads to increased operational efficiency, fewer monitoring work, and lower workload.

IT (IoT / AI) visualization analysis tool

IT(IoT/AI)

When data need to be analyzed, system administrator has to request data from production management, then extract data, summarize, and make a report using softwares such as Excel.

By using the visualization analysis tool, the format of the data you want to see can be created in advance, and everyone could request such data on his/her own personal computer tailored to the need by narrowing down request conditions. Reports for meeting can now be created with a single click, eliminating the need to create forms in Excel, which lead to significant improvements in work efficiency.

CASE /02

CASE /03

IT (IoT / AI) picking system

Industrial Machinery & Tools

Since the worker picks up parts for each vehicle type by looking at lists, it is inevitable that the process would be time-consuming, error-prone, and not efficient as it should. In addition, since the lanes of the part shelves are fixed for each part, the space cannot be used effectively. However, picking system can solve picking mistakes and greatly improves picking speed of workers. Furthermore, even inexperienced workers are able to perform picking work at the same level of efficiency as experienced workers. Free-addressing also lead to part shelves being used more effectively.

Industrial Machinery & Tools Contactless AGV charging system

Industrial Machinery & Tools

1. The operator needs to replace the battery.

→ Easier battery replacement.

2. The replacement work by the worker may cause injury.

→ Improve worker safety.

3. Repeated charging of 0% -100% will shorten battery life.

→ Effectively extends battery life.

4.Charging space and spare battery are required.

→ Charging space is no longer necessary, and spare parts can also be reduced.

CASE /04

CASE /05

Industrial Machinery & Tools Air Compressor & Integrated Control System

Industrial Machinery & Tools

Using integrated control system together with renewal of old compressors, the system can supply optimal air volume according to the amount of air used. Achieving optimal operation by controlling the compressors this way, 30% reduction in power consumption can be seen in 5 years.

If you want to ask anything regarding engineering, please do not hesitate to contact us.

Contact us

If you want to request a quote or ask us anything, feel free to call us right away or use the contact form provided.Company profile download.For our company profile and other files, you can directly download it from here.

FormCompany profile download

For our company profile and other files, you can directly download it from here.

PDF DownloadClick here to contact us by phone or email

- Company(Thai/Japanese)

-

02-336-0711

- Thai (Contact: Koy):

-

095-348-7763

salesadmin@tomaseg.com

- Japanese (Contact: Kozo Nozaki)

-

087-006-2637

nozaki@tomaseg.com

Company Profile

- Company name

- TOMAS ENGINEERING (THAILAND) Co., Ltd.

- MD

- Kozo Nozaki

- Address

-

99/447 Nouvelle Tower Bldg C, Thana City Golf Club,

Bangna-Trad Road KM14., Bang Chalong, Bang Phli District,

Samut Prakan 10540

Google Map

- Telephone

- 02-336-0711

- Year of establishment

- February 2012

- Number of employees

- 15 (3 Japanese, 12 Thai)

Contact Us

Thank you for your interest in our company. Business talks and services.Please contact us using the form below.No. Contact us by phoneNo.